- Production Presses

- SERVO Hydraulic Production Presses

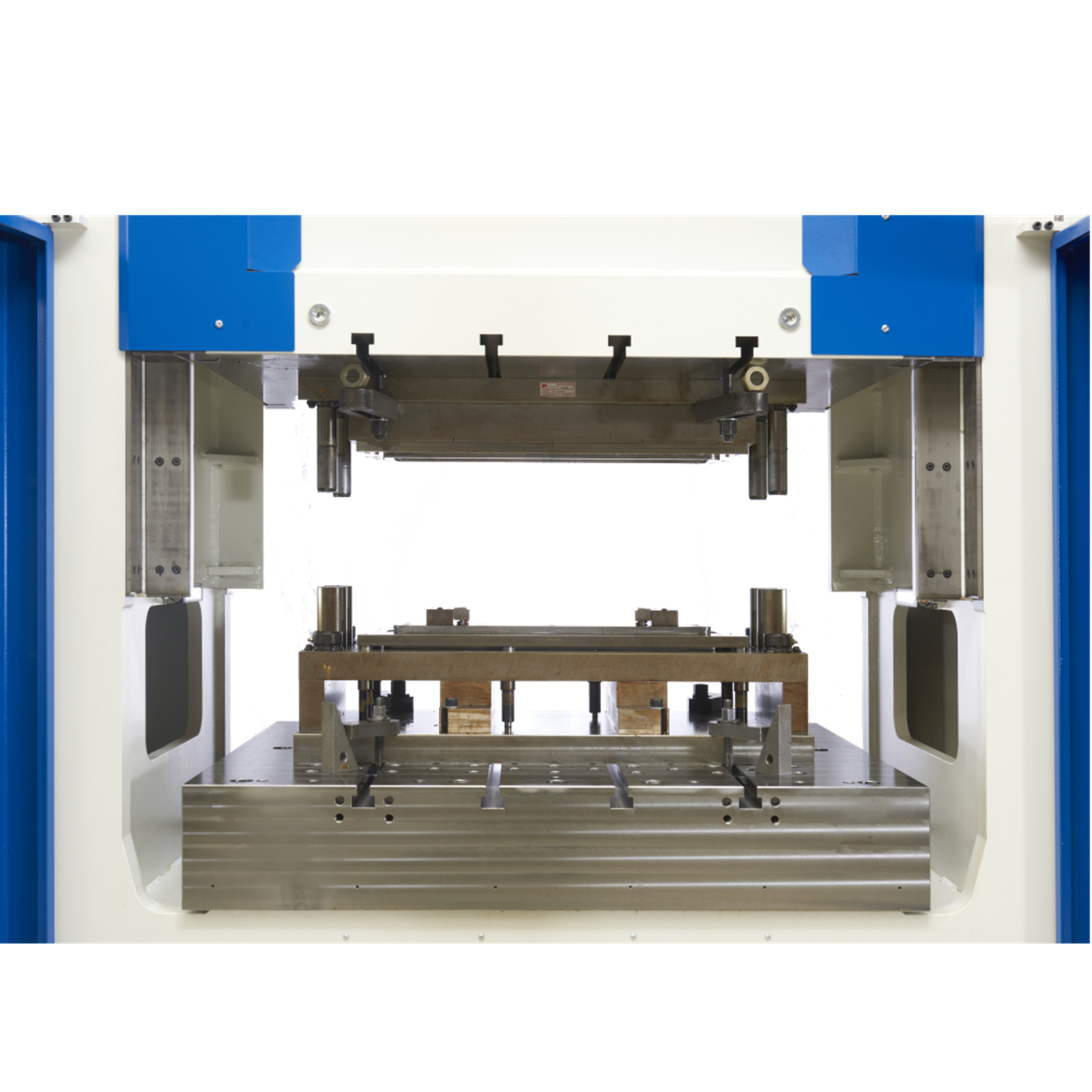

SERVO Hydraulic Production Presses

Accelerate your productivity with the STENHOJ SERVO-Hydraulic Press.

The STENHOJ SERVO-Hydraulic Production Press is our proud answer to modern, sustainable and cost-efficient production, offering an impressive 70% in energy savings compared to a conventional hydraulic press.

Characterised by its rapid speed, great power, remarkably low noise levels and advanced sensors for data intelligence, this is the production press of the future.

Unique Features

- Energy efficient - (-70%)

- High pressure consistency

- Rapid speed - 500 mm/s

- Single and double acting die cushion

- Low noise level - <68dB(A)

- Full force on total stroke length

- Fully programmable PLC

- High accuracy on ram stroke

- Low maintenance costs

- High repeatability

- 100% convertible with standard tooling

Areas of Application

- Hot Pressing

- Cold Pressing

- Deep Drawing

- Bending

- Compressing

- Embossing

- Forging

- Forming

- Grinding

- Stamping

- Punching

- Assembly

- Molding

- Straightening

- Moulding

Specifications

Technology

Speed

Control System

Servo Hydraulic Power Pack

Bed/table and Ram/slide

Cylinders

Ram/Slide Lock

Safety

Servo-Press Guiding Systems

Ram Box with 8 Guided Gibs (PPK)

The ram plate is:

- designed in a welded box construction

- equipped with T-slots for tool clamping

- machined according to DIN 650

- guided by means of eight (8) pieces 90° adjustable guide shoes

- equipped with replaceable Teflon compound inserts

- Replaceable, hardened, and grinded guideways bolted onto the press frame.

Allowable off-centre load of 10% of max. press force

4 Integrated Column Guided Ram Box (PPSP)

The ram plate is:

- designed in a welded box construction

- equipped with T-slots for tool clamping

- machined according to DIN 650

- Through-guided by 4 ram columns and bushings, equipped with Teflon-based compounds

Allowable off-centre load of 7,5% of max. press force

4 Integrated Column Guided Ram Plate (PPS)

The ram plate is:

- designed in a strong solid steel block

- equipped with T-slots for tool clamping

- machined according to DIN 650

- guided with 4 through-going columns and bushings equipped with Teflon-based compounds

Allowable off-centre load of 5% of max. press force.

4 Column Guided Ram Plate (PP4)

The ram plate is:

- designed in a strong solid steel block

- equipped with T-slots for tool clamping

- machined according to DIN 650

- guided by 4 hard chromed steel columns, and 4 bronze bushings

Allowable off-centre load of 3% of max. press force

2 Column Guided Ram Plate (PP2)

The ram plate is:

• designed in a strong solid steel block

• equipped with T-slots for tool clamping

• machined according to DIN 650.

• guided by 2 pcs. hard chromed steel columns and 2 pcs. bronze bushings.