- Production Presses

- H-Type Production Press

H-Type Production Press

Production Presses

Custom built H-frame double-column press with press force from 25 ton to 2000 ton.

The hydraulic production press is designed based on our customers' special needs and specifications and exclusively built from quality materials that guarantee high operational reliability and long service life. The H-type hydraulic press is made with five different optional guiding systems, two optional variable press speed versions and two optional control systems with up to 6 axes.

This high level of design flexibility ensures innovative press solutions and maximum customer satisfaction.

Unique Features

- Press force 25-2000 ton

- Modular design

- 1-6 Axes

- Guided column and flat guided presses

- Fully programmable PLC

- Stenhøj designed cylinder with extra long guides

- Flexible location of power pack

- Die cushion up to 1000 ton pressing force

- Prepared for automation

Areas of Application

- Hot Pressing

- Cold Pressing

- Deep Drawing

- Assembly

- Bending

- Embossing

- Forging

- Grinding

- Stamping

- Compressing

- Forming

- Mounting

- Straightening

Specifications

Pressing Speeds

Control System

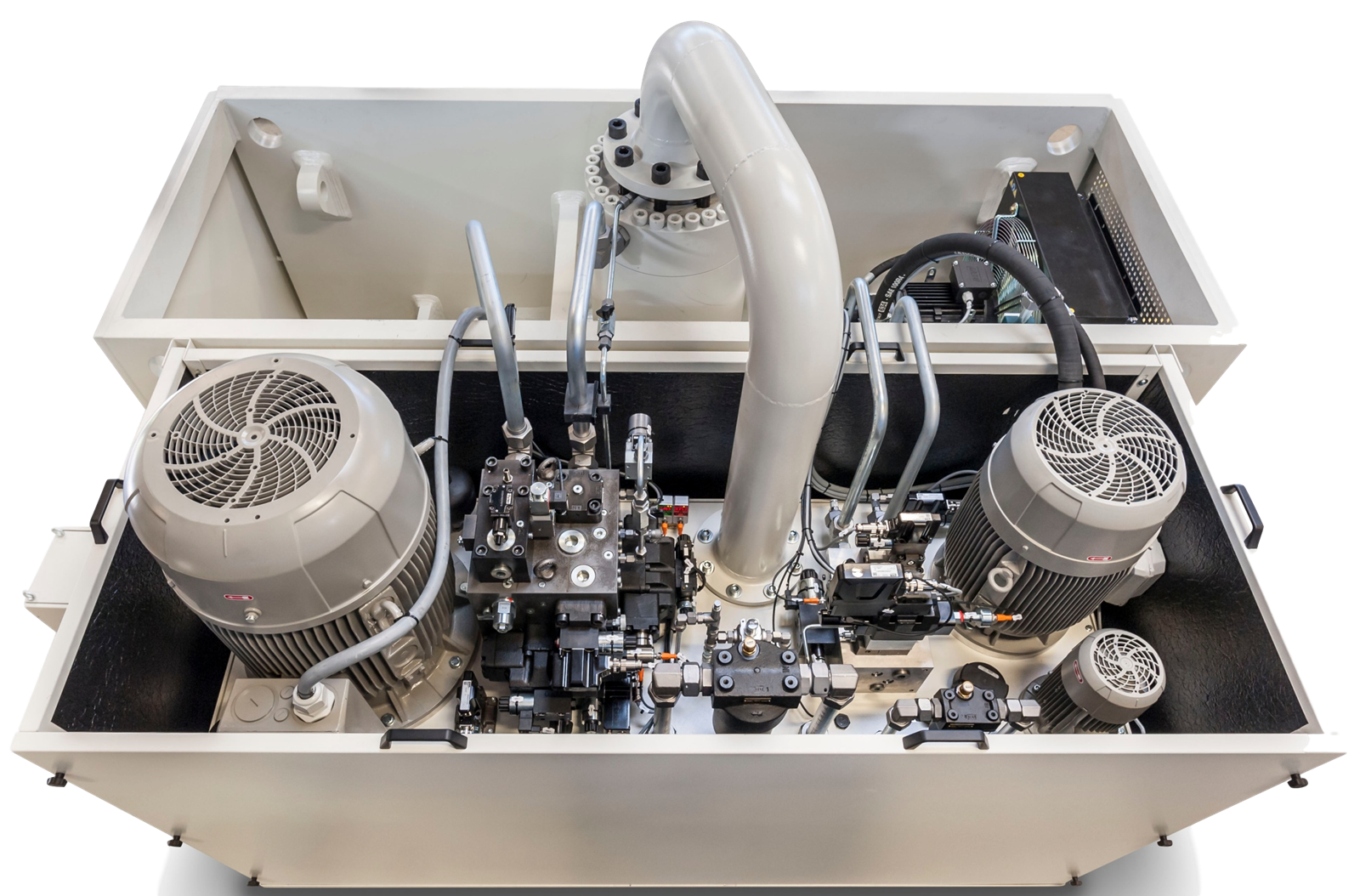

Hydraulic Power Pack

Cylinders

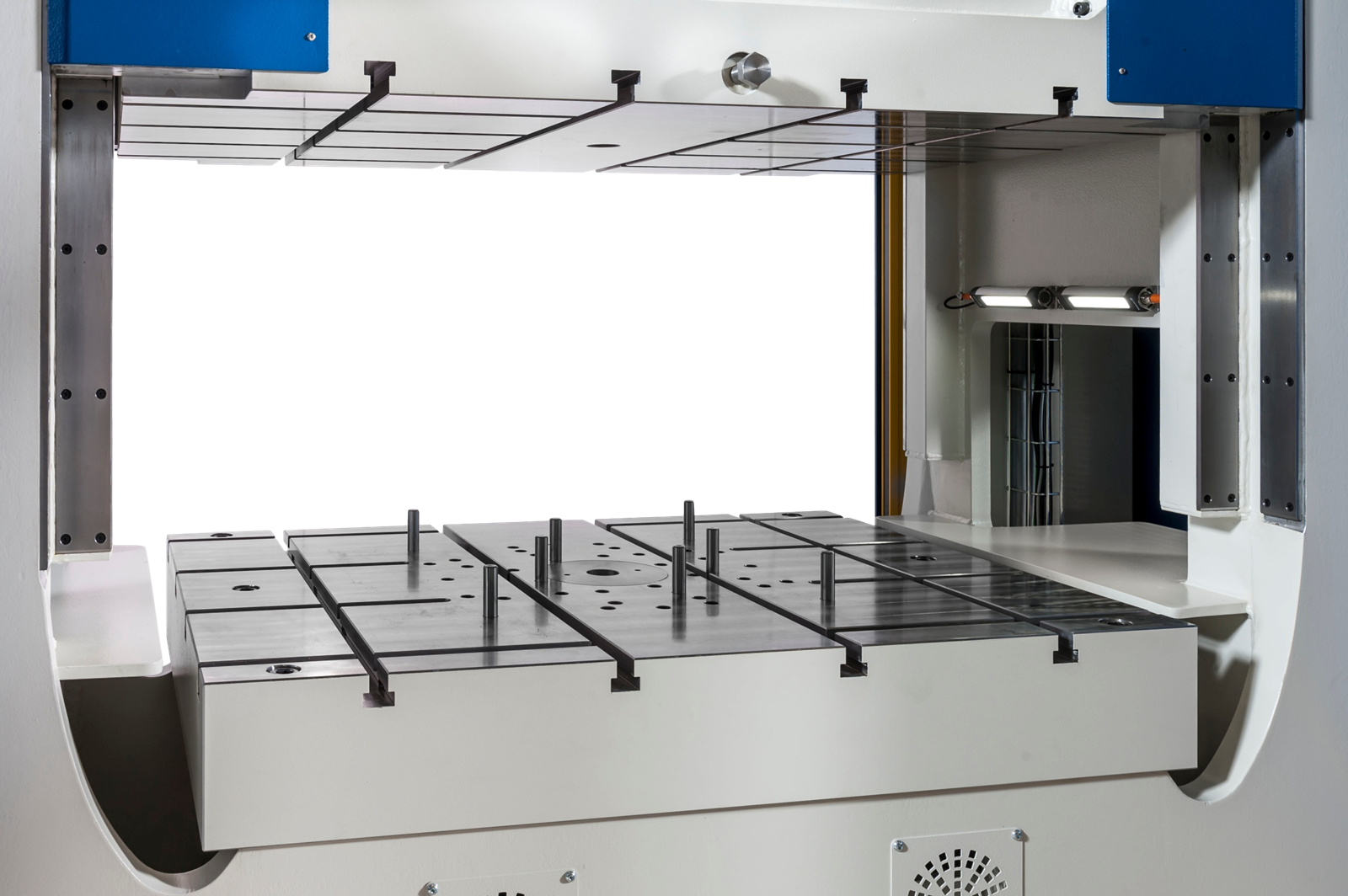

Bed/table and Ram/slide

Ram/slide lock

H-type Guiding Systems

Ram Box with 8 Guided Gibs (PPK)

The ram plate is:

- designed in a welded box construction

- equipped with T-slots for tool clamping

- machined according to DIN 650

- guided by means of eight (8) pieces 90° adjustable guide shoes

- equipped with replaceable Teflon compound inserts

- Replaceable, hardened, and grinded guideways bolted onto the press frame.

Allowable off-centre load of 10% of max. press force

4 Integrated Column Guided Ram Box (PPSP)

The ram plate is:

- designed in a welded box construction

- equipped with T-slots for tool clamping

- machined according to DIN 650

- Through-guided by 4 ram columns and bushings, equipped with Teflon-based compounds

Allowable off-centre load of 7,5% of max. press force

4 Integrated Column Guided Ram Plate (PPS)

The ram plate is:

- designed in a strong solid steel block

- equipped with T-slots for tool clamping

- machined according to DIN 650

- guided with 4 through-going columns and bushings equipped with Teflon-based compounds

Allowable off-centre load of 5% of max. press force.

4 Column Guided Ram Plate (PP4)

The ram plate is:

- designed in a strong solid steel block

- equipped with T-slots for tool clamping

- machined according to DIN 650

- guided by 4 hard chromed steel columns, and 4 bronze bushings

Allowable off-centre load of 3% of max. press force

2 Column Guided Ram Plate (PP2)

The ram plate is:

• designed in a strong solid steel block

• equipped with T-slots for tool clamping

• machined according to DIN 650.

• guided by 2 pcs. hard chromed steel columns and 2 pcs. bronze bushings.